- About us

-

Products

- PCALC - Performance Calculations

- EMS - Environmental Management System

- TSMS - Thermal Stress Monitoring System

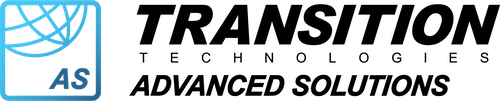

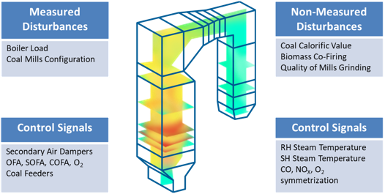

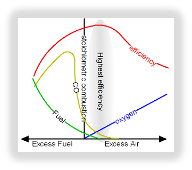

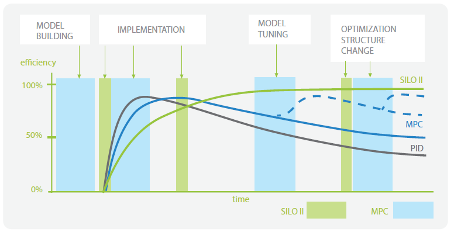

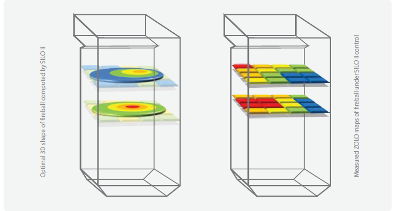

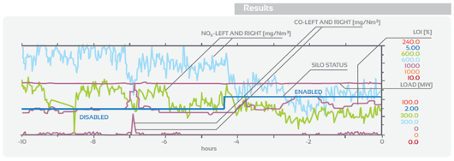

- SILO - Stochastical Immunological Layer Optimizer

- STO - Steam Temperature Optimizer

- URO - Unit Response Optimizer

- ISB - Intelligent Sootblowing

- Workflow Management

- Anomaly Detection

- LOTO - Soft tagout module

- RCM - Reliability-centered Maintenance

- TAMI - Technical Assets Management & Information

- WMS - Warehouse Management System

- LDAR - Liquid Detection and Repair

- VOC - Volatile Organic Compounds

- IT monitoring

- IDS - Intrusion Detection System

- IPS - Intrusion Protection System

- Honeypot

- Context Awareness

- Data diode

- Enterprise log management

- Advanced Logbook

- Reporting Module

- Alarm & Notification System

- BI & Analytics

- Mobile Application

- PIMS - Plant Information Management System

- Settlement/Billing system

- ESB - Enterprise Serial Bus

- ERP/SAP Connector

- EAI – Enterprise Application Integration

- SOA – Service Oriented Architecture

- OPC – OLE for Process Control

Efficient solutions to manage your data.

Optimize your company

- PCALC - Performance Calculations

- EMS - Environmental Management System

- TSMS - Thermal Stress Monitoring System

- SILO - Stochastical Immunological Layer Optimizer

- STO - Steam Temperature Optimizer

- URO - Unit Response Optimizer

- ISB - Intelligent Sootblowing

- FMIS - Fuel Management Information System

- FDM - Fuel Demand Module

- SDH - District Heating System

Data management - key to successs

- Workflow Management

- Anomaly Detection

- LOTO - Soft tagout module

- RCM - Reliability-centered Maintenance

- TAMI - Technical Assets Management & Information

- WMS - Warehouse Management System

- LDAR - Liquid Detection and Repair

Safety first.

- IT monitoring

- IDS - Intrusion Detection System

- IPS - Intrusion Protection System

- Honeypot

- Context Awareness

- Data diode

- Enterprise log management

Report and process 24/365

- Advanced Logbook

- Reporting Module

- Alarm & Notification System

- BI & Analytics

- Mobile Application

- PIMS - Plant Information Management System

- Settlement/Billing system

-

Industries

Oil & gas

Oil and natural gas are major industries in the energy market and play an influential role in the development of the company. The processes and systems involved in producing and distributing oil and gas are highly complex, capital-intensive, and require state-of-the-art technology.

Transition Technologies is closely cooperating with leading O&G companies in the world providing versatile solutions based on cutting-edge software mechanisms and methodologies.

Read more to find out how we can help you.

District heating

Finding ways to deliver sustainable and affordable heating and cooling to our cities is today a must. Moreover, CO2 emissions and 21st century challenges require modern and reliable solutions to ensure local authorities, retail, education and housing customers of uninterrupted supply of consistent-quality product.

Our district heating systems ensure you can promise those customers a low carbon solution that meets environmental regulations - and saves on connection, operation and maintenance costs.

Read more to find out about optimization opportunities.

Agriculture

Farming and agriculture coexist with us ceaselessly since the beginning of humanity and yet this industry requires constant upgrades. Thanks to new advancements in technology, farmers now have access to tools that can help them do all the farming work in less time, more efficiently, and for reduced costs. From robotics and drones to computer vision software, these are just a few examples of modern agriculture technologies that help automate the crop or livestock production cycle.

TT-AS is familiar with problems in the modern world and offers solutions in process automation, forecasting, live-stock and asset management. Read more to find how we can help you.

Pharmaceuticals

As a one of the most innovative branches of economy which originates from pharmacies and chemical companies requires solutions from the most R&D-intensive companies. As a top provider of R&D services, we face challenges with unorthodox solutions and documented results.

Our software can support laboratories in sample management, workflows, lab execution, sample tracking and many more. To find out about solutions suitable for you, read more.

Power Industry

Geopolitical and market factors continue to exert pressure on the energy and natural resources sector, while environmental concerns have boosted the renewables industry. Today, every other industry interacts with energy and natural resources sector. Our business is to maximize your opportunities in a complex and fast-changing market and offer essential insights of your industry.

We offer a holistic environment which covers all nooks and crannies of the software system in a CHP. Also or solutions related to IoT, BI & Analytics, advanced reporting, process visualization and more are protected by cyber security practices.

To acquire more information please read more.

Manufacture & Warehouse

Today most organizations whether they are manufacturing companies or distribution center, they are looking at a warehouse as a strategic tool in Inventory Management. Warehouse is also used for a very important activity called Customer Service and finally Warehouse Operations also do include a lot of Compliance, Documents and Information Management.

Our software solutions confront those problems and let users on many positions in the companie’s hierarchy to have insights and control over the business.

Read more to find out how we can help you.

-

Resources

Our resources

- Contact

Efficient solutions to manage your data.

Optimize your company

- PCALC - Performance Calculations

- EMS - Environmental Management System

- TSMS - Thermal Stress Monitoring System

- SILO - Stochastical Immunological Layer Optimizer

- STO - Steam Temperature Optimizer

- URO - Unit Response Optimizer

- ISB - Intelligent Sootblowing

Data management - key to successs

- Workflow Management

- Anomaly Detection

- LOTO - Soft tagout module

- RCM - Reliability-centered Maintenance

- TAMI - Technical Assets Management & Information

- WMS - Warehouse Management System

- LDAR - Liquid Detection and Repair

- VOC - Volatile Organic Compounds

Bespoke tools, most effective solutions

Safety first.

- IT monitoring

- IDS - Intrusion Detection System

- IPS - Intrusion Protection System

- Honeypot

- Context Awareness

- Data diode

- Enterprise log management

Report and process 24/365

- Advanced Logbook

- Reporting Module

- Alarm & Notification System

- BI & Analytics

- Mobile Application

- PIMS - Plant Information Management System

- Settlement/Billing system

Connect, share and evolve

- ESB - Enterprise Serial Bus

- ERP/SAP Connector

- EAI – Enterprise Application Integration

- SOA – Service Oriented Architecture

- OPC – OLE for Process Control

Oil & rafinery

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed purus ante, fringilla ullamcorper diam id, volutpat volutpat lectus. Nullam sed rhoncus magna.

Heavy Industry (Coal, Steel)

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed purus ante, fringilla ullamcorper diam id, volutpat volutpat lectus. Nullam sed rhoncus magna.

Agriculture

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed purus ante, fringilla ullamcorper diam id, volutpat volutpat lectus. Nullam sed rhoncus magna.

Pharmaceuticals

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed purus ante, fringilla ullamcorper diam id, volutpat volutpat lectus. Nullam sed rhoncus magna.

Telecommunication

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed purus ante, fringilla ullamcorper diam id, volutpat volutpat lectus. Nullam sed rhoncus magna.

Power Industry

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed purus ante, fringilla ullamcorper diam id, volutpat volutpat lectus. Nullam sed rhoncus magna.

Heat Industry

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed purus ante, fringilla ullamcorper diam id, volutpat volutpat lectus. Nullam sed rhoncus magna.

Energy & Natural Resources

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed purus ante, fringilla ullamcorper diam id, volutpat volutpat lectus. Nullam sed rhoncus magna.

Manufacture & Warehouse

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed purus ante, fringilla ullamcorper diam id, volutpat volutpat lectus. Nullam sed rhoncus magna.

Efficient solutions to manage your data.

Optimize your company

- PCALC - Performance Calculations

- EMS - Environmental Management System

- TSMS - Thermal Stress Monitoring System

- SILO - Stochastical Immunological Layer Optimizer

- STO - Steam Temperature Optimizer

- URO - Unit Response Optimizer

- ISB - Intelligent Sootblowing

Data management - key to successs

- Workflow Management

- Anomaly Detection

- LOTO - Soft tagout module

- RCM - Reliability-centered Maintenance

- TAMI - Technical Assets Management & Information

- WMS - Warehouse Management System

- LDAR - Liquid Detection and Repair

- VOC - Volatile Organic Compounds

Bespoke tools, most effective solutions

Safety first.

- IT monitoring

- IDS - Intrusion Detection System

- IPS - Intrusion Protection System

- Honeypot

- Context Awareness

- Data diode

- Enterprise log management

Report and process 24/365

- Advanced Logbook

- Reporting Module

- Alarm & Notification System

- BI & Analytics

- Mobile Application

- PIMS - Plant Information Management System

- Settlement/Billing system

Connect, share and evolve

- ESB - Enterprise Serial Bus

- ERP/SAP Connector

- EAI – Enterprise Application Integration

- SOA – Service Oriented Architecture

- OPC – OLE for Process Control

Oil & rafinery

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed purus ante, fringilla ullamcorper diam id, volutpat volutpat lectus. Nullam sed rhoncus magna.

Heavy Industry (Coal, Steel)

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed purus ante, fringilla ullamcorper diam id, volutpat volutpat lectus. Nullam sed rhoncus magna.

Agriculture

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed purus ante, fringilla ullamcorper diam id, volutpat volutpat lectus. Nullam sed rhoncus magna.

Pharmaceuticals

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed purus ante, fringilla ullamcorper diam id, volutpat volutpat lectus. Nullam sed rhoncus magna.

Telecommunication

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed purus ante, fringilla ullamcorper diam id, volutpat volutpat lectus. Nullam sed rhoncus magna.

Power Industry

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed purus ante, fringilla ullamcorper diam id, volutpat volutpat lectus. Nullam sed rhoncus magna.

Heat Industry

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed purus ante, fringilla ullamcorper diam id, volutpat volutpat lectus. Nullam sed rhoncus magna.

Energy & Natural Resources

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed purus ante, fringilla ullamcorper diam id, volutpat volutpat lectus. Nullam sed rhoncus magna.

Manufacture & Warehouse

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed purus ante, fringilla ullamcorper diam id, volutpat volutpat lectus. Nullam sed rhoncus magna.